Details

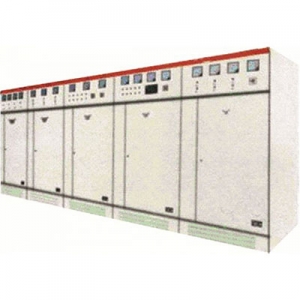

Product category: product center switch cabinet series

Product Description: modular design

Easy assembly

Good scalability

Scope and purpose of use:

GGD AC low-voltage distribution cabinet is applicable to the power distribution system with AC 50Hz, rated working voltage of 380V and rated working current of 6300A for power plants, substations, factories and mining enterprises and other power users. It is used for power conversion, distribution and control of power, lighting and distribution equipment.

GGD AC low-voltage distribution cabinet is a new type of low-voltage distribution cabinet designed according to the requirements of the majority of power users and design departments and based on the principles of safety, economy, rationality and reliability. The product has the characteristics of high breaking capacity, good stability, flexible electrical scheme, convenient combination, strong seriality, practicability, novel structure and high protection grade. It can be used as an updated product of low-voltage switchgear.

GGD AC low voltage distribution cabinet complies with GB7251 1-2005 / iec60439-1:1999 low voltage switchgear and control equipment.

Service conditions:

l. The ambient air temperature shall not be higher than + 40 ℃, not lower than - 5 ℃, and the average temperature within 24 hours shall not be higher than + 35 ℃.

2. For indoor installation and use, the altitude of the place of use shall not exceed 2000m.

3. The relative humidity of the surrounding air shall not exceed 50% when the maximum temperature is + 40 ℃, and a large relative humidity is allowed at a lower temperature

(e.g. 90% at + 20 ℃). Consideration should be given to the possibility of occasional condensation due to temperature changes.

4. When installing the equipment, the inclination with the vertical plane shall not exceed 5 degrees.

5. The equipment shall be installed in places without violent vibration and impact, as well as places where it is insufficient to cause corrosion of electrical components.

6. If users have special requirements, they can negotiate with the manufacturer.

Technical performance and features:

1. Basic electrical parameters

2. Main circuit scheme

The main circuit of GGD cabinet is designed with 129 schemes and 298 specifications in total (excluding the schemes and specifications derived from the function change of auxiliary circuit and the change of control voltage)

among

Ggdl has 49 schemes and 123 specifications

Ggd2 has 53 schemes and 107 specifications

Ggd3 has 27 schemes and 68 specifications

The main circuit scheme is selected after soliciting the opinions of the majority of design and user departments, which increases the scheme required by the power plant. The rated current is increased to 3150A, which is suitable for distribution transformers of 2000kVA and below.

In addition, in order to meet the needs of reactive power compensation, ggj1 and ggj2 capacitor compensation cabinets are designed, with 4 main circuit schemes and 12 specifications in total.

3. Auxiliary circuit scheme

The design of auxiliary circuit is divided into two parts: common scheme and power plant scheme. There is enough space in GGD cabinet to install secondary components. At the same time, a special lmz3d current transformer has been developed to meet the needs of relay protection attached to power plants and special users.

4. Main bus

Considering the price ratio and the feasibility of replacing copper with aluminum, single aluminum busbar shall be adopted when the rated current is 1500A and below (depending on the user's requirements). When the rated current is greater than 1500A, copper busbar shall be used.

The overlapping surface of the bus shall be treated by tinning process.

5. Selection of electrical components

A. GGD cabinet mainly adopts more advanced electrical components that can be mass produced in China, such as me, hsw1, hsm1, rmw1, rmm1, etc. at the same time, according to the principle of economy and rationality and on the premise of fully considering the feasibility, some available old products, such as dz10, etc., are retained instead of obsolete products, and advanced electrical components are selected according to the development of domestic components.

B. Hd13bx and hs13bx rotary operated knife switches are special components designed to meet the needs of the unique structure of GGD cabinet. It changes the original operation mode of the mechanism and retains the advantages of old products. It is a practical new electrical component.

C. For example, when the design department selects new electrical components with better performance and more advanced technology according to the needs of users, due to the good installation flexibility of GGD cabinet, it is generally not difficult to update the manufacturing and installation of electrical components.

D. In order to further improve the dynamic stability of the main circuit, ZMJ combined bus clamp and insulation support for GGD cabinet are designed. The bus clamp is made of high-strength and flame-retardant PPO composite thermoplastic, with high insulation strength, good self extinguishing performance and unique structure. It can be easily combined into single bus clamp or double bus clamp by adjusting the building block. Insulation support is a sleeve type molding mechanism with low cost and high strength, which solves the defect of insufficient creepage distance of old products.

Structural features:

1. The cabinet body of GGD AC low-voltage distribution cabinet adopts the form of general cabinet, and the frame is locally welded and assembled with 8MF cold-formed steel. The frame parts and special supporting parts are supplied by the designated section steel manufacturer to ensure the accuracy and quality of the cabinet. The parts of the general cabinet are designed according to the module principle, and there are 20 die mounting holes, with high general coefficient. Can make the factory realize production. It not only shortens the production cycle, but also improves the work efficiency.

2. In the design of GGD cabinet, the heat dissipation problem in the operation of the cabinet is fully considered. There are different numbers of heat dissipation slots at the upper and lower ends of the cabinet. When the electrical components in the cabinet are heated, the heat rises and is discharged through the upper slot, while the cold air is continuously supplemented into the cabinet by the lower slot. It is a sealed cabinet to form a natural ventilation channel from bottom to top to achieve the purpose of heat dissipation.

3. According to the requirements of modern process product modeling design, GGD cabinet adopts the method of golden section ratio to design the cabinet shape and the division size of each part, so as to make the whole cabinet beautiful and generous.

4. The cabinet door is connected with the frame by rotating shaft movable hinge, which is convenient for installation and disassembly. A mountain shaped rubber strip is embedded at the folding edge of the door. When opening the door, the strip between the door and the frame has a certain compression stroke, which can prevent the direct collision between the door and the cabinet and improve the protection grade of the door.

5. The instrument door equipped with electrical components is connected with the frame with multiple strands of soft copper wire, and the mounting parts in the cabinet are connected with the frame with knurled screws, forming a complete grounding protection circuit as a whole.

6. Polyester orange baking paint is selected as the finishing coat of the cabinet, which has strong adhesion and good texture. The whole cabinet is in matte tone, avoiding dazzling effect and creating a more comfortable visual environment for the personnel on duty.

7. The top cover of the cabinet can be removed when necessary to facilitate the assembly and adjustment of the main bus on site. The four corners of the cabinet top are equipped with lifting rings for lifting and shipping.

8. The protection grade of the cabinet is IP30. Users can choose between IP20 and IP40 according to the needs of the environment.